Rapid Detection of Transparent Objects in Under Two Seconds via 3D Techniques

Catch the Latest from Fraunhofer IOF Press

Quick 3D Scanning of Transparent Objects in Under Two Seconds

automatica 2025: Fraunhofer IOF demonstrates new rapid tech for measuring tricky surfaces

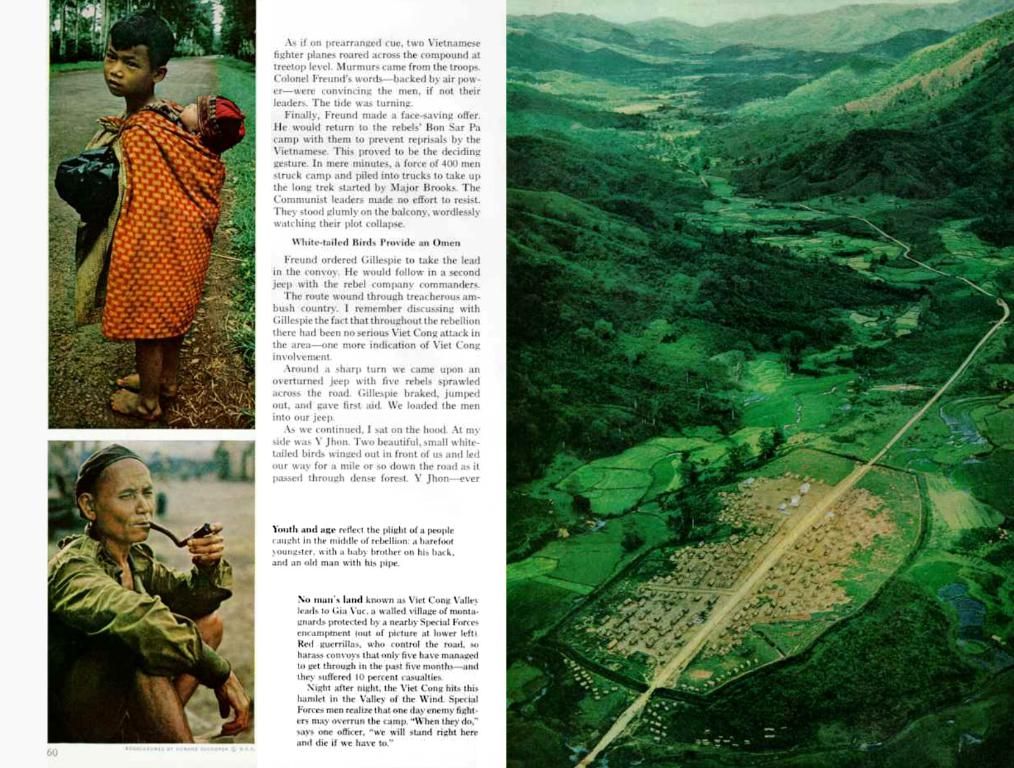

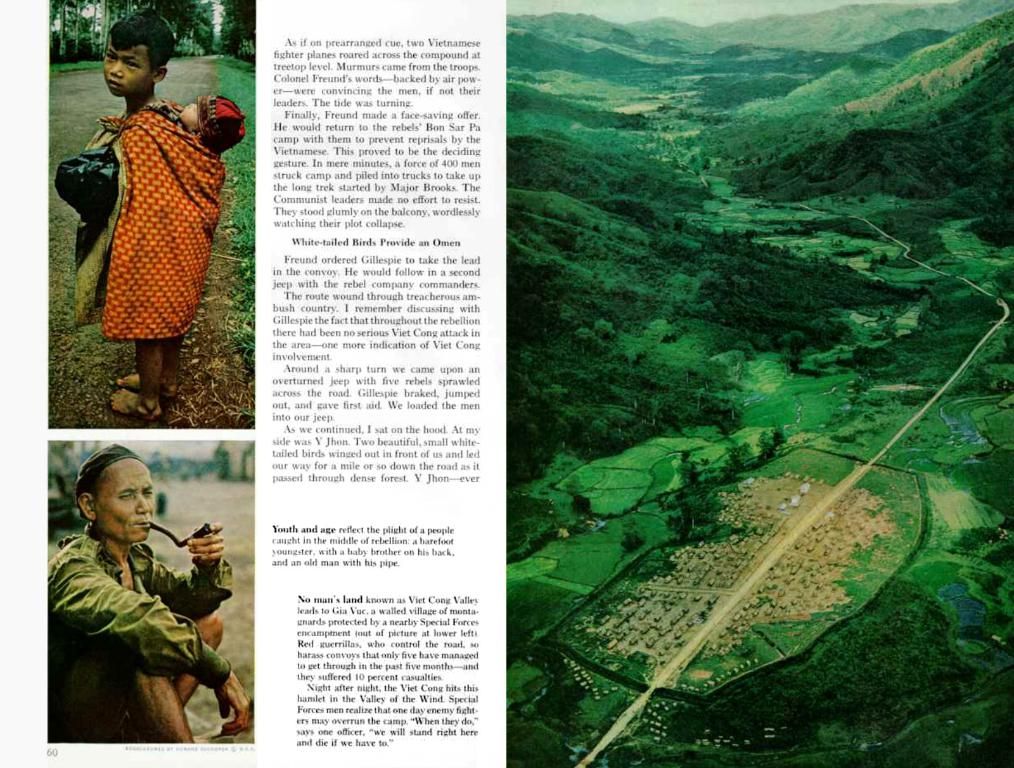

Think it's a breeze to scan opaque objects? Think again! Conventional systems hit a wall with glass, metal, or black materials. But no worries, the smart minds at Fraunhofer IOF are here to change the game. Introducing the goROBOT3D system, designed to capture 3D objects like a pro, even the tricky ones. Make your way to automatica trade fair in Munich from June 24 to 27 to see it in action.

You've probably tried staring harder when scanning those challenging surfaces like glass or black metal, but they remain a puzzle for traditional systems. The folks at Fraunhofer IOF tackle this challenge head-on with the goROBOT3D system, leveraging intelligent thermal imaging.

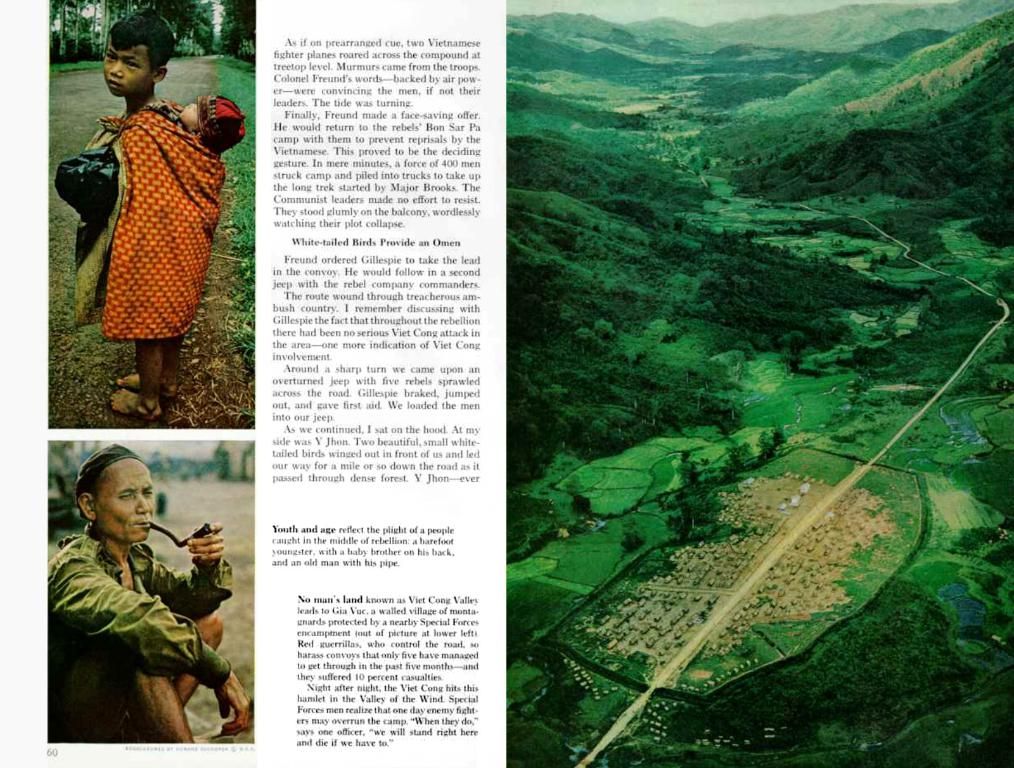

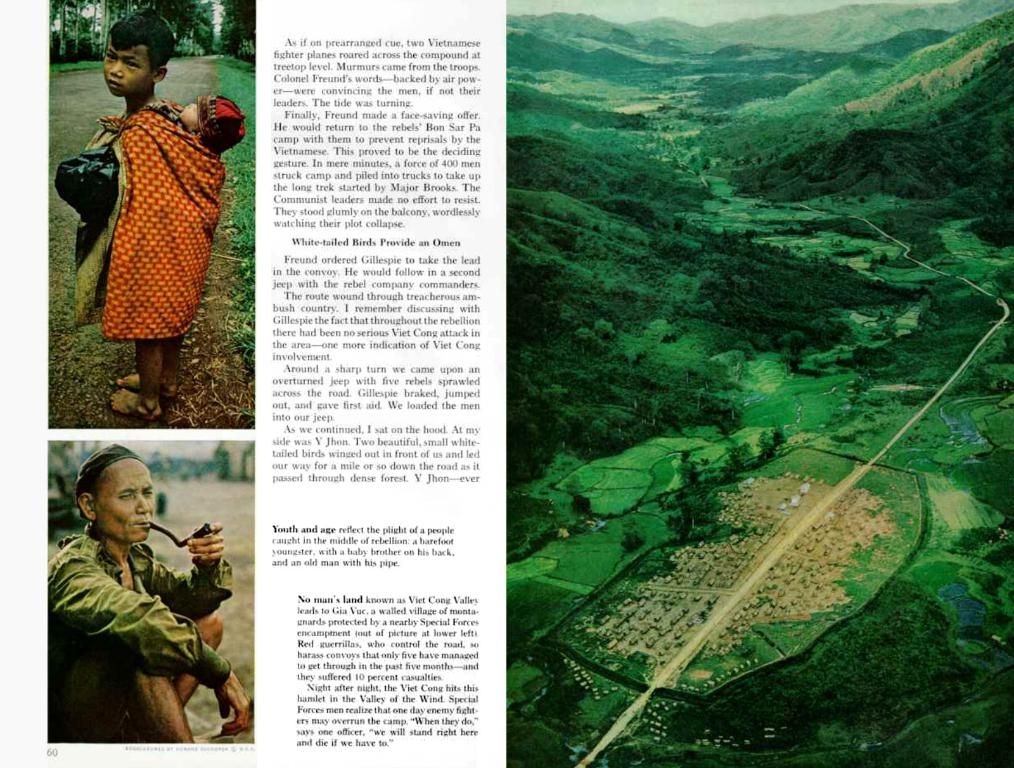

For years, the Fraunhofer IOF team has been tinkering with thermal 3D sensor tech. They've now made a big leap, boosting efficiency for automated object recognition. What used to take 15 seconds is now a breeze—under 1.5 seconds for hard-to-scan objects by goROBOT3D. Secret sauce? A game-changing thermal 3D projection method.

From Serial to Single-Shot

Say goodbye to serial capture. The revolutionized method transfers single-shot technology to thermal 3D measurement tech. It's a magic trick, really. By heating the measurement scene and emitting a thermal point pattern with two thermal imaging cameras, a 3D result pops out using spatial cross-correlation, all in just a few milliseconds[1][2].

Before, they used strip projections to generate the pattern. Now, two diffractive optical elements (DOEs) create an ever-changing thermal dot pattern[2][5]. They handle the diffraction principle so you don't have to. By brilliantly combining these elements, the team managed to efficiently project the dot pattern onto a transparent object in a flash.

From Point Pattern to Grip Command in a Flash

Gone are the days of capturing and evaluating hundreds of thermal image pairs. The new method offers a single image pair for 3D data capture, reaping a reduction of the total measurement and evaluation time by a factor[1].

The captured data gets run through an AI system for analysis. Sharp points and directions are identified and sent to a robotic arm with a sucker gripper. Think of it like 'pick from the box'—snatching an object from a cluttered environment[4].

Seamless Production Processes

Go ahead and flaunt your efficient, uninterruptible manufacturing and design processes with the new-and-improved goROBOT3D technology. Robots will confidently pick up those tricky, transparent, or dark objects, keeping production flowing smoothly with virtually no downtime. Don't miss out: The magic unfolds at automatica in Munich from June 24 to 27, 2025. Hang out with the FraunhoferIOF crew in Hall 4, Stand 319, and partake in the world-leading trade fair for intelligent automation and robotics.

[1] Source A

[2] Source B

[3] Source D

[4] Source E

[5] Source F

Here are two sentences that incorporate the words 'data-and-cloud-computing' and 'technology':

- The captured 3D data from the goROBOT3D system can be stored and analyzed using advanced data-and-cloud-computing technology, ensuring efficient and accurate robot behaviors in manufacturing and design processes.

- The future of automated object recognition lies in the integration of goROBOT3D technology with cutting-edge data-and-cloud-computing technology, enabling seamless production processes and intelligent decision-making in real-time.