Top Three Strategies for Upgrading Switchgear Equipment

In the heart of industrial facilities lies the electrical infrastructure, often serving as the heartbeat of these operations. One crucial component of this system is switchgear, a key player in the distribution of electrical power.

Switchgear, often referred to as the "guardian of the grid," has a lifespan of 25-40 years. However, outdated switchgear poses non-trivial risks to industrial facilities. Delaying its replacement can lead to unplanned downtime, safety hazards, and significant financial losses.

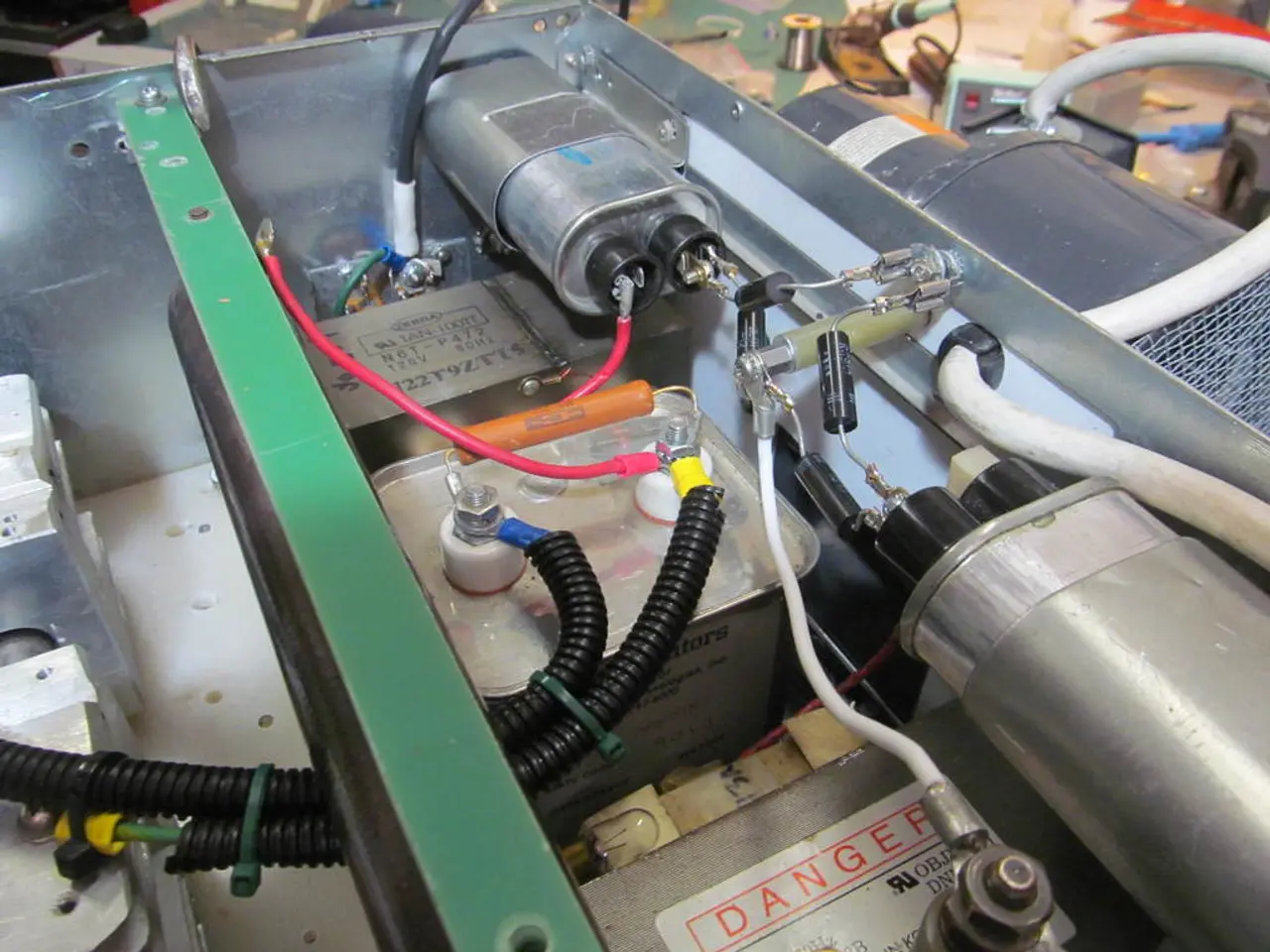

Fortunately, upgrading or retrofitting aging switchgear offers a solution. This process helps avoid unplanned downtime, safety hazards, and significant financial losses by extending equipment life, incorporating modern safety features, and improving reliability and performance.

Key benefits of switchgear upgrades include:

- Extending Equipment Life: Modernizing aging switchgear can add up to 30 years of useful life to existing equipment, delaying the need for full replacement.

- Reducing Unplanned Downtime: Upgrades, such as replacing circuit breakers and components, reduce the risk of sudden failures that can cause costly production halts, especially important given current 60-week lead times for new equipment.

- Enhancing Safety: Incorporating modern safety and protection technologies minimizes hazards to personnel by preventing electrical faults and arc flash incidents.

- Lower Costs Compared to Replacement: Retrofitting can save over $500,000 in equipment and up to $250,000 in labor versus full system replacement.

- Improved Performance and Compliance: Upgrades bring switchgear and associated control systems up to current standards, improve energy efficiency, and enable better monitoring and predictive maintenance to avoid failures.

- Minimized Operational Disruption: Retrofitting projects typically require less downtime (around 25-30 weeks) than full replacements (up to 60 weeks), allowing facilities to maintain productivity during upgrades.

Proactive updating of switchgear is an essential practice to prevent issues before they start. The three best practices for updating switchgear include "guarding your guardian," emphasizing the importance of maintaining switchgear to prevent potential malfunctions and equipment failure.

Waiting until switchgear fails for replacement can result in costly unplanned downtime and safety hazards. Many companies wait to replace outdated switchgear at the 40-year mark, despite recognizing its potential issues.

In conclusion, upgrading or retrofitting aging switchgear leverages modern technologies to improve reliability and safety, preventing costly unplanned outages and protecting industrial operations financially and physically. Electrical infrastructure is crucial for industrial facilities that power automated systems, and switchgear plays a vital role in regulating the flow of electricity, protecting against overcurrents and short circuits, and ensuring safe and efficient power distribution.

- Upgrading switchgear, which serves as the guardian of the industrial grid, can prevent non-trivial risks, such as unplanned downtime, safety hazards, and significant financial losses, often associated with delayed replacement.

- By embracing modern technologies in switchgear upgrades, industrial facilities can improve performance and safety, extend equipment life, and minimize operational disruption, thereby aligning with the financial and physical protection needed for manufacturing, finance, technology, and other sectors in the industry.