Transformation in Industrial Efficiency: Magnetic Brakes Leading the Way

In the realm of technology, magnetic brakes are making a significant impact, offering unprecedented benefits across various sectors such as manufacturing, logistics, and food processing.

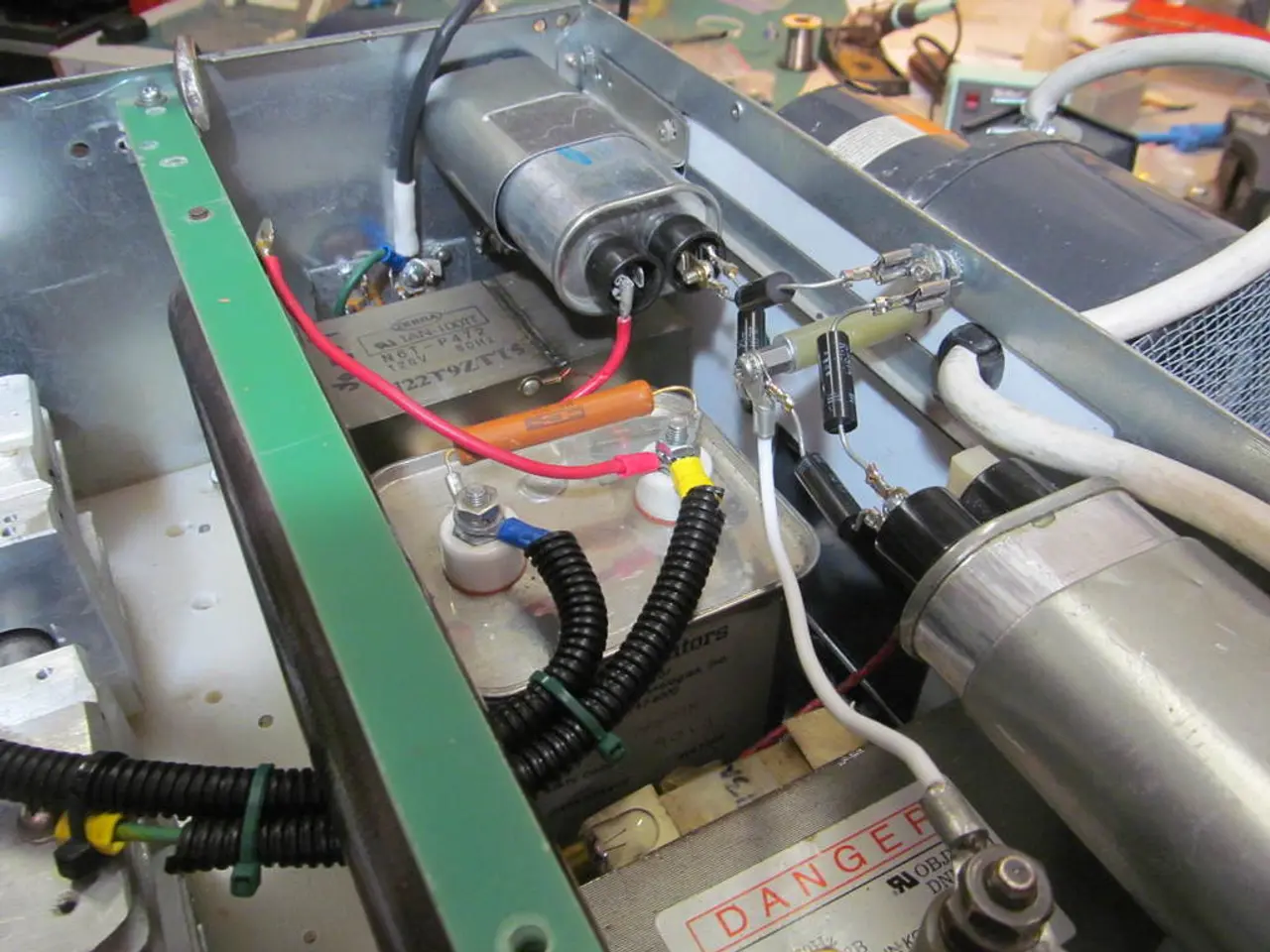

At the heart of magnetic brakes is a unique design where the stator and rotor have opposite poles, ensuring maximum magnetic attraction. This design provides a significant economic advantage by minimizing energy usage and reducing maintenance needs.

Magnetic brakes, equipped with energy-efficient features, contribute significantly to the green transition. They allow businesses to reduce energy consumption without compromising performance, making them a pivotal advancement in technology.

The precision and consistency offered by magnetic brakes translate into improved product quality and operational smoothness. In continuous production environments such as printing, packaging, textile manufacturing, and conveyor systems, magnetic brakes provide highly accurate torque control, which is crucial for maintaining product quality.

In manufacturing, magnetic brakes enable smoother tension and speed control in processes like film extrusion and steel rolling, reducing material damage and downtime. The variable and automatic control types of magnetic brakes allow real-time adjustments, ideal for high-speed automotive and electronics production lines.

In logistics and food processing industries, magnetic brakes help maintain gentle handling of products, reducing product damage and spoilage risks. The eco-friendly nature of magnetic brakes supports compliance with stringent environmental regulations, potentially resulting in economic incentives or avoiding fines.

With the right design, magnetic brake systems can operate in hazardous or explosive environments without posing a risk, as they are fully enclosed and can operate in extreme conditions.

GRW, a leader in magnetic brake technology, offers products that revolutionize the way machinery operates in various industries. The company has collaborated with leading manufacturers and food processing companies to equip their systems with magnetic brakes, resulting in reduced maintenance costs, improved safety standards, and reduced electricity bills.

Research into intelligent magnetic systems that can learn and adapt to varying conditions is a promising development in the field of industry automation. The integration of advanced control systems will allow magnetic brakes to operate with even greater precision and flexibility, monitoring real-time performance and adjusting settings to optimize efficiency according to changing demands.

Embracing magnetic brake technology is an investment in the future of sustainability, economy, and safety, as it enhances performance, lowers costs, and streamlines processes. With their unmatched efficiency, reliability, and energy savings, magnetic brakes represent a pioneering technology poised to revolutionize operations across various sectors.

- Within the industry, magnetic brake technology plays a significant role in the finance sector as it enables businesses to reduce energy consumption while maintaining peak performance, thereby cutting down operational costs.

- In the realm of technology, advancements in magnetic brake systems, such as intelligent magnetic systems, have potential applications in motor vehicle industries, offering enhanced safety and energy savings through real-time adjustments and adaptability to varying conditions.